ID:7

1205G high-end upgraded version

$9300

$14000

Component Introduction

Product Video

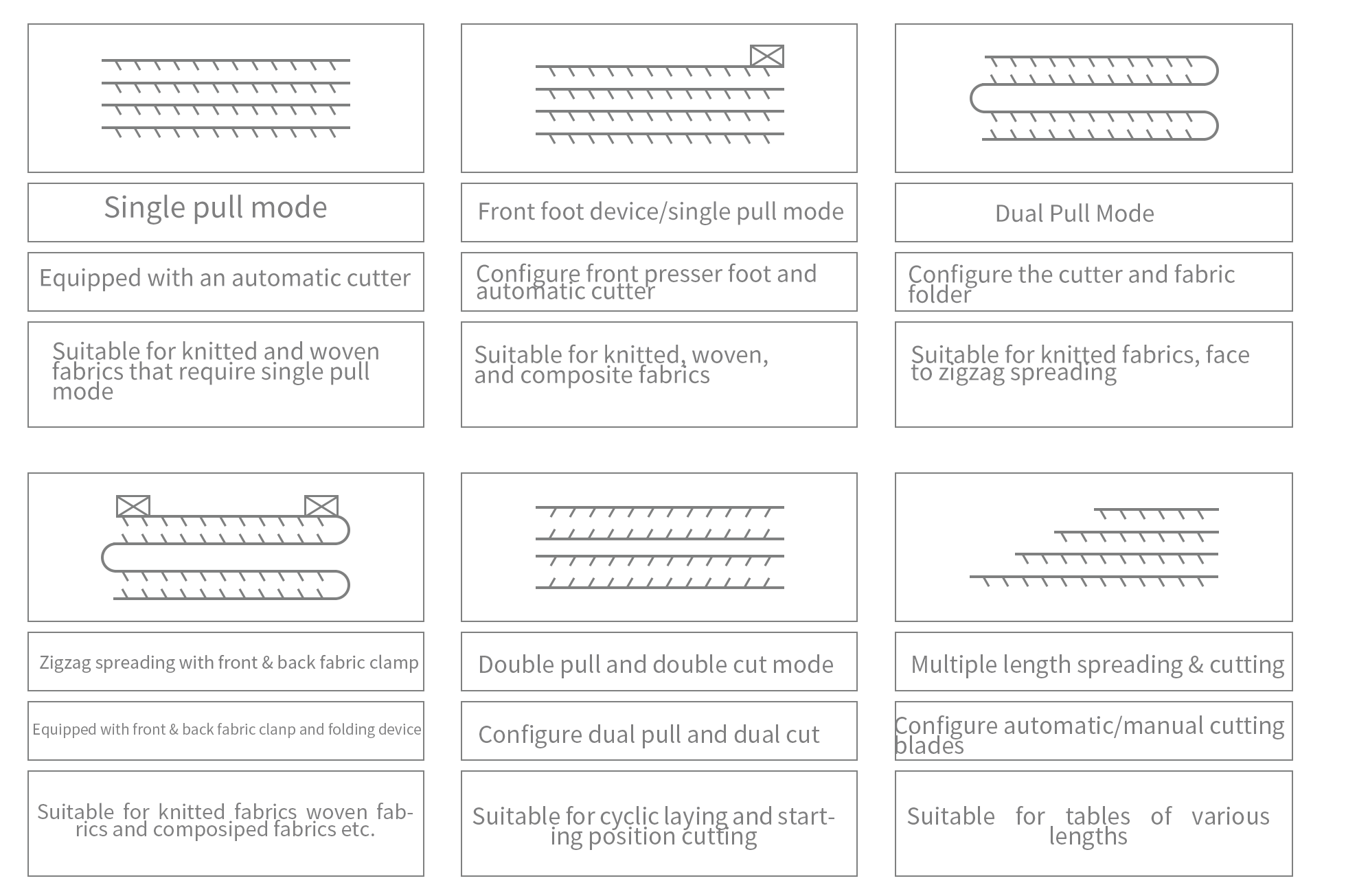

Laying mode

Overview

Ideal models suitable for various factories, with a particularly high tolerance for all types of fabrics, regardless of fabric selection; This model is very suitable for manufacturers with a variety of factory fabrics, and can be said to be the best choice, such as outdoor products, medical fabrics, clothing, bags, home textiles, shoes and hats, packaging, toys Wait, there is a machine model that is widely used in these industries for knitting and weaving.

Key Features

| 1202Economical and affordable type | |

|---|---|

| Appearance Style | streamline |

| Transmission mode | Chain/sprocket |

| control center | |

| Controller response | 2-millisecond response; 100KHZ high-speed calculation |

| Touch Screen | Seven inch high-definition high brightness screen |

| encoder | A subtle response; 100KHZ high-speed response |

| relay | 12A ultra-high current |

| Optoelectronic safety range | Safety sensing range 5mm-200mm |

| driving system | |

| inverter | Non sensory side vector control |

| servo system | Automatic adaptive adjustment |

| power | Temperature resistance of 150 degrees |

| Lifting system | Hard alloy gearbox |

| Structural materials | |

| Rough surface material | Remove static abrasion resistant rough surface skin |

| Transportation pipeline | Aerospace specific hard aluminum alloy |

| Sheet metal accessories | State owned enterprises produce hard alloy steel |

| screw | Large brand 304 stainless steel high-strength bolts |

| Whole machine structure | Multi pass bending steel plate welding gantry structure |

| Intelligent configuration system | |

| automatic compensation | ☒ |

| Automatic blade sharpening | ☑ |

| Internet of Things | ☑ |

| Remote troubleshooting | ☑ |

| data analysis | ☑ |

| fault detect | ☑ |

| System parameter saving | ☑ |

| Automatic tension adjustment | ☑ |

| Automatic laying function | |

| Double pull fabric (front and rear presser foot) | ☑ |

| Whole roll fabric laying | ☑ |

| Automatic edge alignment | ☑ |

| Loosen the fabric and lay it out | ☑ |

| Automatically adjust fabric folding height | ☑ |

| No fabric automatically returns to the origin | ☑ |

| The fabric is pre loosened | ☑ |

| Automatic splicing fabric | ☑ |

| Automatic trimming (preventing curling) | ☑ |

| Technical Parameter | |

| 1205G-160 | |

| voltage | AC220±5% 50HZ/60HZ |

| power | 1KW |

| Laying speed | 0-80m/min(Can be controlled) |

| Single pull height | 20CM (customizable) |

| Double pull height | 20CM (customizable) |

| Weight bearing capacity (fabric) | 80KG |

| Fabric diameter | 50CM (customizable) |

| Machine size(For reference only) | 2370mm*1600mm*800mm |

| Size of export wooden box(For reference only) | 2450mm*1630mm*1250mm |

| 1205G-190 | |

| voltage | AC220±5% 50HZ/60HZ |

| power | 1KW |

| Laying speed | 0-95m/min(Can be controlled) |

| Single pull height | 20CM (customizable) |

| Double pull height | 20CM (customizable) |

| Weight bearing capacity (fabric) | 80KG |

| Fabric diameter | 50CM (customizable) |

| Machine size(For reference only) | 2660mm*1600mm*800mm |

| Size of export wooden box(For reference only) | 2750mm*1630mm*1250mm |

| 1205G-210 | |

| voltage | AC220±5% 50HZ/60HZ |

| power | 1KW |

| Laying speed | 0-95m/min(Can be controlled) |

| Single pull height | 20CM (customizable) |

| Double pull height | 20CM (customizable) |

| Weight bearing capacity (fabric) | 80KG |

| Fabric diameter | 50CM (customizable) |

| Machine size(For reference only) | 2860mm*1600mm*800mm |

| Size of export wooden box(For reference only) | 3000mm*1630mm*1250mm |