ID:1

Blue Lotus 1202 Classic

$7200

$8500

Component Introduction

Product Video

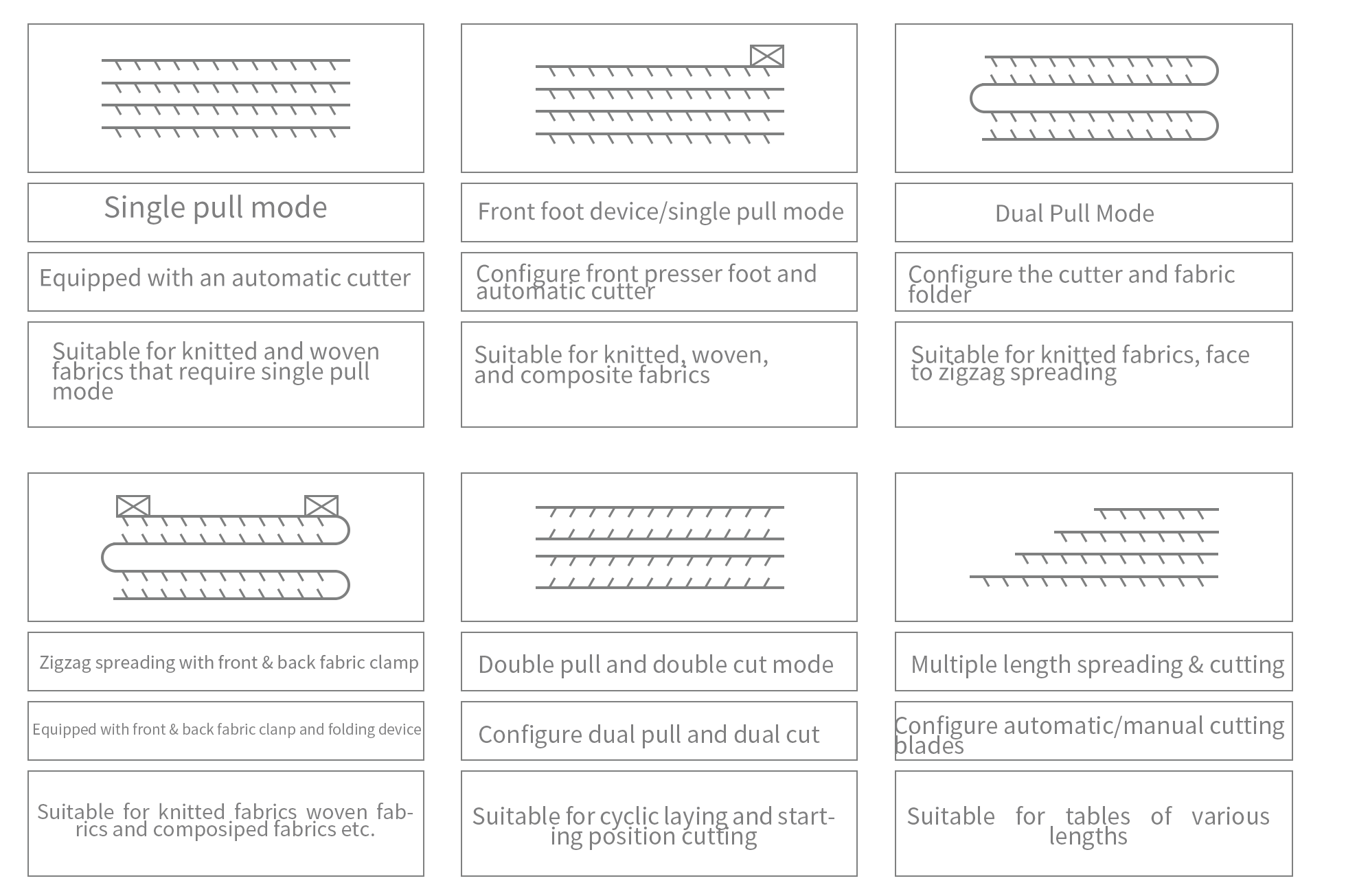

Laying mode

Overview

This model has a simple structure, is easy to maintain, and has a low failure rate. It mainly focuses on weaving low elasticity fabrics with spreading needles; The fabric wheel adopts chain transmission, which is durable and long-lasting; Using a servo motor to drive the fabric wheel, the fabric placement is smoother and the fabric laying is precisely controlled, resulting in a uniform and neat laying effect; The overall cost-effectiveness is extremely high.

Key Features

| 1202Economical and affordable type | |

|---|---|

| Appearance Style | streamline |

| Transmission mode | Chain/sprocket |

| control center | |

| Controller response | 2-millisecond response; 100KHZ high-speed calculation |

| Touch Screen | Seven inch high-definition high brightness screen |

| encoder | A subtle response; 100KHZ high-speed response |

| relay | 12A ultra-high current |

| Optoelectronic safety range | Safety sensing range 5mm-200mm |

| driving system | |

| inverter | Non sensory side vector control |

| servo system | Automatic adaptive adjustment |

| power | Temperature resistance of 150 degrees |

| Lifting system | Hard alloy gearbox |

| Structural materials | |

| Rough surface material | Remove static abrasion resistant rough surface skin |

| Transportation pipeline | Aerospace specific hard aluminum alloy |

| Sheet metal accessories | State owned enterprises produce hard alloy steel |

| screw | Large brand 304 stainless steel high-strength bolts |

| Whole machine structure | Multi pass bending steel plate welding gantry structure |

| Intelligent configuration system | |

| automatic compensation | ☒ |

| function | ☒ |

| Automatic blade sharpening | ☒ |

| Internet of Things | ☒ |

| Remote troubleshooting | ☒ |

| data analysis | ☑ |

| fault detect | ☑ |

| System parameter saving | ☑ |

| Automatic tension adjustment | ☑ |

| Automatic laying function | |

| Double pull fabric (front and rear presser foot) | ☑ |

| Whole roll fabric laying | ☑ |

| Automatic edge alignment | ☑ |

| Loosen the fabric and lay it out | ☑ |

| Automatically adjust fabric folding height | ☑ |

| No fabric automatically returns to the origin | ☑ |

| The fabric is pre loosened | ☑ |

| Automatic splicing fabric | ☒ |

| Automatic trimming (preventing curling) | ☑ |

| Technical Parameter | |

| 1202-160 | |

| voltage | AC220±5% 50HZ/60HZ |

| power | 1KW |

| Laying speed | 0-80m/min(Can be controlled) |

| Single pull height | 27CM (customizable) |

| Double pull height | 27CM (customizable) |

| Weight bearing capacity (fabric) | 80KG |

| Fabric diameter | 50CM (customizable) |

| Machine size(For reference only) | 2370mm*1600mm*800mm |

| Size of export wooden box(For reference only) | 2450mm*1630mm*1250mm |

| 1202-190 | |

| voltage | AC220±5% 50HZ/60HZ |

| power | 1KW |

| Laying speed | 0-80m/min(Can be controlled) |

| Single pull height | 27CM (customizable) |

| Double pull height | 27CM (customizable) |

| Weight bearing capacity (fabric) | 80KG |

| Fabric diameter | 50CM (customizable) |

| Machine size(For reference only) | 2660mm*1600mm*800mm |

| Size of export wooden box(For reference only) | 2750mm*1630mm*1250mm |

| 1202-210 | |

| voltage | AC220±5% 50HZ/60HZ |

| power | 1KW |

| Laying speed | 0-80m/min(Can be controlled) |

| Single pull height | 27CM (customizable) |

| Double pull height | 27CM (customizable) |

| Weight bearing capacity (fabric) | 80KG |

| Fabric diameter | 50CM (customizable) |

| Machine size(For reference only) | 2860mm*1600mm*800mm |

| Size of export wooden box(For reference only) | 3000mm*1630mm*1250mm |